In a plant, each of the unit operations commonly happen in particular person vessels or sections of the plant referred to as models. Often, one or more chemical reactions are concerned, but different ways of adjusting chemical (or material) composition could also be used, such as mixing or separation processes. The method steps could also be sequential in time or sequential in area along a stream of flowing or moving materials; see Chemical plant. For a given quantity of a feed (enter) material or product (output) materials, an expected quantity of material can be decided at key steps in the process from empirical knowledge and materials steadiness calculations. Since the process is all occurring within one container, forces that would probably cause segregation of the mixture are also vastly lowered. Tumblers are used in processes that involve the mixing of free-flowing powders and pastes. Proven here’s a double cone tumbler. Can handle massive volumes. Simple to wash, which allows for better manufacturing flexibility. Little put on on equipment.

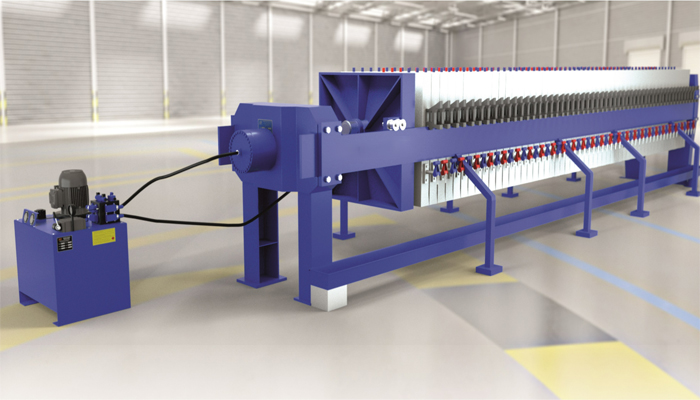

They can applicate in industries similar to mining, chemical, and wastewater treatment. The computerized filter press operates on a continuous cycle, reducing the necessity for manual labor and increasing productiveness. Considered one of the principle benefits of utilizing a filter press is its effectivity. The system can operate constantly, reducing downtime and increasing productiveness. The liquid often exists the plates by nook ports into a manifold. Three. When the appropriate valves are open in the manifold, the liquid exits the press through the filtrate outlet. Because the feed pump builds stress, the solids kind inside the chambers until they’re full of filter cake. Four. As soon as the chambers are full of filter cake, the filling cycle is complete, and the filter press is ready to be emptied. 5. The press is then opened, and the plates are moved apart. A hydraulic power pack in a filter press machine controls the cylinders that assist transfer the plates. It’s self-contained and primarily consists of parts reminiscent of a reservoir, motor, and hydraulic pump. It transfers power from one location to a different utilizing fluid.

With today’s unstable market, material costs are rapidly climbing and deliveries are being extended. A used or rebuilt filter from Avery Filter Firm could be simply what you were searching for to fulfill a tight funds and/or schedule constraints. Avery Filter Firm is the only company in the used gear subject specializing solely and buying, promoting and rebuilding filtration tools. This expertise assures you that you’ll receive the Best Rubber membrane plate in india possible recommendation in making your equipment choice. Additionally, you will benefit from our expertise as we help you in selecting the appropriate filter media on your application. The drum filter press uses a rotating drum because the filtration medium, the slurry passes through the surface of the drum and the solid particles regularly kind a cookie. The rotation of the drum makes the filtration course of continuous. Suitable for eventualities the place continuous processing is required, such because the chemical, food and mining industries. Notably appropriate for solid-liquid separation wants where viscous or fibrous supplies are present. This is vital for each maximum yield the place a high value liquid is your product and excessive solids-content material, the place decreased moisture content in the final cake is crucial. Our Membrane Filter Press provides a dryer cake that can be obtained using high feed pumping strain in a standard filter press. It considerably reduces or eliminates downstream thermal drying and associated costs in energy and time.

This could sometimes be restricted to only using air to blow out the slurry core. Automated wash system. Computerized wash programs should be thought-about more closely when taking a look at aspect beam presses. Entry for cloth washing is restricted due to the minimal opening space between the cakes and the restricted access as a result of beams running alongside the facet of the press. They will also be useful in overhead beam presses when operator availability for cloth washing is limited. Our workers consists of experienced Project Managers, Engineers, Operators, Technicians, Fabricators, Scientists, Mechanics, and Health and Safety Professionals. Our objective is to fulfill and exceed consumer expectations whereas providing quality, protected and cost-efficient services. In some cases, our purchasers find that the worth of the supplies returned to the plant pays partially for the cost of the sludge dewatering service. View our most recent liquidation of vessels, heat exchangers, columns & drum heaters. Overview of Hydrogen, Ammonia and Methanol PlantsIn an industrial setting, a fixed bed plug movement reactor sends gas and liquid to downflow trickle mattress reactors. This space is the place hydrocracking and hydrotreating occur. Hydrotreating is a standard process within the petroleum business. The effect of the squeeze is to physically compress the filter cake and pressure out additional moisture held inside the cake giving a drier end end result. Alternately in conjunction with recessed plates as a extra economical possibility. The membrane technology is gaining elevated acceptance because it reduces subsequent processing or disposal prices for filter cake.